Pick your favourite brand of chocolate and then turn the pack over and look at its ingredients. Other than the rare few, most chocolates including a lot of artisan brands add lecithin to their chocolates.

So what exactly is lecithin?

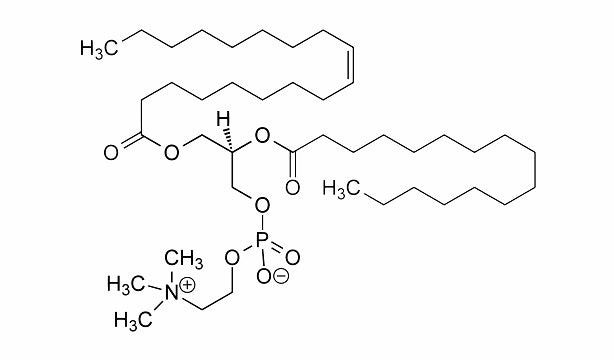

Lecithin is the generic term used for a group of fatty substances that attract both water and fat. It lowers the surface tension between liquids which allows them to spread and combine quicker. In simpler words, it does 2 things – first acts as a glue to bind both water and fat and second it brings 2 liquids with different properties together as one thus making it easier to handle.

Lecithin is found in almost all packaged foods that have a high percentage of fat in it. It is there in your salad sauces, mayonnaise, chocolates and every other food you can think of.

Sources of lecithin

Most of the globally produced lecithin is made from soy. The rest come from sunflower oil, rapeseeds oil, cottonseed oil, milk and at times from eggs.

The process of extracting lecithin can be done chemically or mechanically. A lot of the lecithin used worldwide is extracted chemically using solvents such as hexane, ethanol, acetone, petroleum ether or benzene. Unless specified otherwise, soy used for the lecithin is almost always genetically modified.

Lecithin, especially sunflower lecithin, can also be produced using mechanical extraction where lecithin is separated using a centrifuge and then dried.

Chocolate and lecithin

Chocolate is a mixture of solids suspended in cocoa butter. Solids can be in the form of cocoa beans, milk and sugar or just about anything else. If made from just cocoa beans, the cocoa butter content in chocolate can vary based on various conditions. This may result in chocolate that may be a little more viscous. This can be resolved either by grinding them finer or adding more cocoa butter to reduce the viscosity of the chocolate. A quick trick employed by some (including some artisan chocolate makers) is to add some lecithin. Just around 0.5% of lecithin can create the same effect as adding 3-4% of cocoa butter. This ends up saving money and effort for the chocolate makers who can get away without adding additional cocoa butter or grinding them perfectly.

Industrial chocolate is normally made by pressing cocoa beans, splitting them into cocoa butter and cocoa solids. Chocolate makers tend to use cocoa butter to make white chocolate or at times sell them to the cosmetics industry. At times cocoa butter is also replaced by another fat and just a little cocoa butter is added to replace the same. Adding lecithin not only helps homogenize the mixture but also as mentioned previously helps it flow freely. Since cost is a major factor in industrial chocolate, lecithin plays an important role.

Machines play an important role in chocolate making; especially for large chocolate makers. Chocolate is pumped around through pipes before it is converted into chocolate. It requires chocolate to flow smoothly through the pipes without getting stuck. Lecithin not only makes it cheaper to produce chocolate but also make handling chocolate easier in a lot of large chocolate making setups.

Though lecithin is normally not used in chocolate for its emulsifying (bringing water and fat together) properties, at times it does help.

In this age of modern retail, food is expected to have a long shelf life. And chocolates which is extra sensitive to even a small change in temperature can bloom (the fat or sugar separating and coming up to the surface in the form of white spots) or simply get deformed. Lecithin helps improve the shelf life of chocolate by preventing it from blooming easily.

Now let’s see the other side.

The other side of lecithin

At Oona we believe that lecithin is good for companies but not for the person who is consuming the chocolate. We have reasons for it.

Lecithin does make the entire process of chocolate making easier but at the same time it completely changes the texture, aromas and flavour of chocolate. A good chocolate is flavourful, aromatic and has a smooth texture that melts cleanly on your palate. When chocolate may be a little difficult to handle, chocolate makers tend to add extra cocoa butter to it. This lends an extra layer of creaminess to the chocolate. Adding lecithin completely changes chocolate. Lecithin flattens the beautiful flavours, some which are too nuanced to be even noticeable to most palates. It suppresses the often subtle aromas that exist in the chocolate. Along with the flavours and aromas, the texture undergoes a drastic change. It becomes waxy. When melting on the palate, instead of the smooth melt of a good chocolate, this one feels like a layer of melted wax on the palate. In the end, even a good chocolate loses all of its most loved and desirable characteristics after the addition of lecithin. What remains is just a faint reminder of what was once upon a time chocolate.

Soy lecithin which is the most common form on lecithin is almost always genetically modified. Moreover it is extracted using harmful chemicals and then bleached to an acceptable yellow colour. Sunflower lecithin which is the second most used lecithin is considered to be much cleaner. However not all sunflower lecithin are created equal. The process by which it is extracted and the way sunflower is grown defines the quality of the lecithin. Hence it is important to note whether it has been mechanically extracted and is organically or naturally grown.

Lecithin may be a boon for chocolate makers in a bid to increase profits but it’s a bane for the person consuming that chocolate. A good chocolate is about beautiful flavours and the ingredients that go into it. We recently tasted a dark chocolate from Mumbai made with one of the best cacao beans from South America but with added lecithin. On tasting it, we felt utter sadness. Adding just a little lecithin had literally destroyed the beautiful flavours in it. At the same time, the ones we had tried from the United States made with cocoa beans from the same plantation were mind-blowing. It applied to the Indian origin chocolate that they make compared to ones made without any lecithin as well.

Making good chocolate is creating chocolate that is different from the way it is created in the world today. It is more than just about chocolate. It is about bringing about a change for the better. Adding lecithin puts the good chocolate makers in a category just above the industrial ones because they are contributing to standardization of chocolate while portraying the opposite. We all deserve truly amazing chocolate and truly amazing food and most importantly the absolute truth from companies. It’s time for a change.

Share:

Theobromine vs caffeine. What is better?

What is ceremonial cacao? History, modern day ceremonies and beyond.